Theory of Constraints (TOC)

Gaining Better Project Control

Gaining Better Project Control

Controlling a Project

This is one of the most difficult things in project management. Let’s be honest with one-self. How many times have we found ourselves in a situation where-in the project members wait till the very last minute to initiate a task and typically complete it burning the midnight oil? How many times have we asked ourselves the question – why can’t I have a better control over the project? Controlling projects is a nightmare. The bigger they get, the more chaos and uncertainty creeps into them. But this can be managed and controlled using a management methodology called Critical Chain Project Management (CCPM) and its tool such as Pro*Chain.

This article focuses on the management philosophy called Theory of Constraints on which CCPM is based on.

Theory of Constraints (TOC)

The Theory of Constraints is a management philosophy that was introduced by Dr. Eliyahu M. Goldratt, in his 1984 book titled ‘The Goal’. It assists businesses in achieving their goals by providing a mechanism to gain better control of their initiatives. According to Goldratt, the strength of any chain, either a process or a system, is only as good as its weakest link [1]. TOC is a systemic way to identify constraints that hinder system’s success and to effect the changes to remove them.

TOC consists of separate, but interrelated concepts such as – the performance measurement processes, logical thinking processes and logistics. Goldratt also developed the tool, known as ‘the five focusing steps’, to help systems deal with constraints.

Performance Measurement Processes

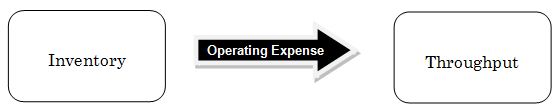

As per Goldratt, there are three key performance indicators – throughput, inventory and operating expense.

- Throughput is the rate at which the system generates money through sales and not through production [1]. Goods are not considered as an asset unless and until they are sold.

- Inventory is the money invested in goods that the firm intends to sell or the material that the firm intends to convert into saleable items.

- Operating Expense is the money that the firm spends in converting the Inventory into throughput [1].

The typical objective of a firm is to increase the throughput by reducing the inventory and the operating cost, thereby in-turn increasing the profit, return-on-investment and cash-flow.

A constraint is anything that hinders the firm from achieving its goal of increasing throughput and/or decreasing inventory or operating cost. For example – a constraint can be capacity, material, logistics, the market (demand) and behavior.

Logical Thinking Process

The logical thinking process of TOC gives us a series of steps that combine cause-effect, experience and intuition to gain knowledge. This is known as the ‘five focusing steps’. And they are:

Step 1: Identification of system’s constraint

Step 2: Decide how to exploit the system’s constraint

Step 3: Sub-ordinate everything else to the decisions made on step-2.

Step 4: Elevate the system’s constraint

Step 5: If a constraint is broken in step-4, go back to step-1. But do not allow a new constraint to creep in.

This five-step process allows one to identify the largest constraint that overshadows all of the others. As soon as a constraint is resolved, then the next weakest link becomes a priority and need to be addressed. Thus, this is an ongoing system improvement process.

Now, let’s take a look at a project management methodology called Critical Chain Project Management (CCPM) that makes use of the principles of Theory of Constraint (TOC).

Critical Chain Project Management (CCPM)

The Gartner Group estimates that companies spend close to $2 billion per year on early generations of project management software and associates services. And even after this much investment, most of the projects are delivered beyond schedule or over budget or under scope. As per the Standish group report in 2009, only 32% are successful, with 44% were challenged and 24% met failure [2].

So, why do so many projects fail?

Lack of flexibility and resistance to change are the main reasons for project failures. Traditional project management assumes that once a well thought out project plan is created and followed, it will provide good, expected results. It fails to address the practical uncertainties such as requirement change, work not completed on time, delayed approvals, etc. that typically occur in any project.

This is where Critical Chain Project Management (CCPM) is different. CCPM focuses on task due dates and interim milestones in a project. It emphasizes on the completion of the most important tasks in the project plan as quickly as possible and delivering of the completed project as quickly as possible. The following two conceptual situations in project management using CCPM – a) Resource Constrained Situations and b) Optimum Usage of Buffer, leads to the creation of three types of buffer between tasks –

- Project Buffer (PB) – This is the amount of buffer that’s added to the end of the project. Set, typically, between 20% and 50% of the duration of activities in critical chain.

- Feeding Buffer (FB) – This is the amount of buffer time at the end of a sequence of activities.

- Resource Buffer (RB) – This is an alert that’s used to indicate that a resource is needed to perform an activity. This alert can be set a few days before the actual activity begins.

The typical steps that would be followed in using CCPM would be –

-

- Remove ‘Safety Time’ and reduce the activity duration by 50%.

- Create schedules on late finish dates.

- Remove resource constraints

- Identify critical chain

- Add project buffer of 50% of the critical chain tasks duration to the end of the project.

- Add feeding buffer to the end of the chain of non-critical tasks.

Traditional Project Management Approach vs CCPM

Successful implementation of CCPM requires significant shift in the approach by the whole team. The following table clearly defines the shift in approach between traditional project management and project management using CCPM.

| Traditional Approach |

CCPM Approach |

|

Focus on interim milestones |

Focus on tasks: The work takes as long as it takes without multi-tasking |

|

Multi-tasking – working on several key tasks at the same time |

Focus in a single task, complete it and hand it on |

|

Task duration estimates are typically “padded” to account for multi-tasking |

Task durations area estimated as a range (optimistic, mean and pessimistic estimates). |

|

Multiple priorities make it impossible to fully focus on one task |

Tasks and projects have clear priorities – highest-priority task first |

|

“Parkinson’s Law” – work expands to fill the available time |

Define “done” for each task. Focus on it, complete it, and hand it over. |

|

Work is started just in time to finish it before it’s due |

Start tasks as soon as predecessor tasks are completed, hand them on as fast as possible |

|

Finishing something early means the next person has more time |

Finishing something early means the next task starts early |

|

Rigid Schedules |

Flexible Schedules (but with a definite target) |

Objectives

There are two key objectives in using CCPM –

- Improve the reliability of the delivery of projects

- Reduce cycle time for development projects

The above-mentioned objectives can be achieved by adopting the following key management principles –

- Develop aggressive yet achievable and realistic schedules.

- Communicate clearly and transparently throughout the project. This allows us to identify risks early and take corrective action as well as identify when a project could move more quickly.

- Work with focus on the task at hand, rather than multi-tasking. This results in quicker task completion and also higher quality.

- Start tasks when they are ready to be started, devote full energy to their completion, and pass them on as soon as they are completed.

The following pointers along with the key management principles will provide the basic guideline for ensuring project success by providing a tool for gaining better control of the project.

1 – Creating Credible Schedule

Tasks and resources drive the timeline of a project. The project schedule is initially created by having the tasks needed to deliver an output (deliverable) created and then, the duration needed to complete the task (assuming that 100% effort is spent on doing that task and that all inputs to that task are available) is calculated. Execution of the project is managed by:

- Ensuring team members understand which tasks are driving the project’s timing (the critical chain) and enabling focused effort on the project’s key tasks.

- Communicating project progress so that team members can prepare to focus on their tasks as soon as their tasks are ready start.

- Tracking project completion and use of the project buffer, to identify emerging problems that could threaten the commitment date.

2 – Single-task focus

When Critical Chain Schedule is built, it’s assumed that a task can be completed in an aggressive, but achievable duration and we add project buffers to handle risks when they materialize. One other big assumption of schedule creation is that a resource will spent 100% effort in doing an activity. That is, the resource will do and only do one activity at a time and see it through to completion (no multi-tasking).

3 – Clear and Transparent Communication

Clear and transparent communication needs to be done right from the moment the schedule is created and until the project is closed. As tasks are done on a focused manner and the activity passes from one resource to another, the communication between one who completes a task and the one who initiates the following task becomes very important. The main difference of CCPM from the traditional project management is that there’s no deadline for an activity in CCPM. This means that there are no deadlines to hit or miss. When an activity takes more than the planned duration then it eats into the available buffer, and when an activity takes less than the planned duration then it releases the respective buffer duration.

Thus, managing a project using CCPM enables a project team to drive system productivity upwards through its core principles. And it also ensures that the project gets delivered on time and within the planned budget. By using CCPM tools such as Pro*Chain one can get a clear visibility of the activities that are to get delayed (through fever charts), and thus empowering the project manager with the knowledge (buffer status being yellow or red) to take immediate action and rectify the situation that might impact the final project schedule, thereby providing a better control of the project.

References

[1] James F. Cox III and John H. Blackstone Jr., ’Theory of Constraints’, APICS Dictionary, Editors, 9th edition, Falls Church,VA, 1998.[2] Jorge Dominique (01st Jul 2009), ‘The Curious Case of the CHAOS Report 2009’, Referenced 11th Apr’, 2011, http://www.projectsmart.co.uk/the-curious-case-of-the-chaos-report-2009.html

Author

Roopesh Kumar, B.E, M.B.A, PMP. is based in Japan and works as a Program Manager for a leading IT firm. He has 16 years of IT experience of which 10+ has been either as a project manager or a program manager. He has worked in several countries such as the U.S, Japan, India and Singapore. He has been handling IT programs or projects that have had 30 to 40 members distributed in different parts of the world. His management interests are in human resource management and human interactions in cross-cultural settings. In his free time, he loves reading science fiction novels, playing tennis, playing table-tennis and hiking.

You can reach him at roopesh@kyotodesign.com

Copyright Project Perfect