Automation Systems Project Management

Part 1

Abstract

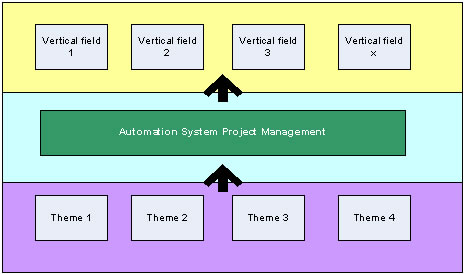

This paper tries to investigate project management knowledge expansion to a vertical industry – automation systems. First the literature carefully limits the scope of automation systems. It then gathers themes from literature review, map themes between vertical automation systems, PMI common themes and other technical / managerial disciplinary themes. The managerial and technical specific requirements are gathered, understood, and solution themes are proposed for each requirement.

At the end, the literature concludes an integrated management framework is preferable to support automation systems project management. PMO, program and operation management should also get involved so that the whole automation systems project management movement can get enough support within the enterprise.

This is Part 1 of the white paper.

Introduction / Background

What is Automation System?

Automation System is defined as the use of control systems and information technologies to reduce the need for human work in production of good and services. The author joined the Project Management Institute Automation Systems Community of Practice.

Although the discipline “Automation System” has been established for long, mostly as a topic in industrial engineering, there are not many specialized, referential or academic association between Project Management and Automation System. (Wikipedia – automation systems, 2011)

Also, automation system has been mostly perceived as a sub-branch of industrial engineering, which is a branch of engineering dealing with the optimization of complex processes or systems.

Industrial engineering is concerned with the development, improvement, implementation and evaluation of integrated systems of people, money, knowledge, information, equipment, energy, materials, analysis and synthesis, as well as the mathematical, physical and social sciences together with the principles and methods of engineering design to specify, predict, and evaluate the results to be obtained from such systems or processes.

Depending on the sub-specialities involved, industrial engineering may also be known as operations management, management science, operations research, systems engineering, or manufacturing engineering In health care, industrial engineers are more commonly known as health management engineers or health systems engineers. ( Wikipedia – industrial engineering, 2011)

Methods – Stretching Scope from Traditional to New industries

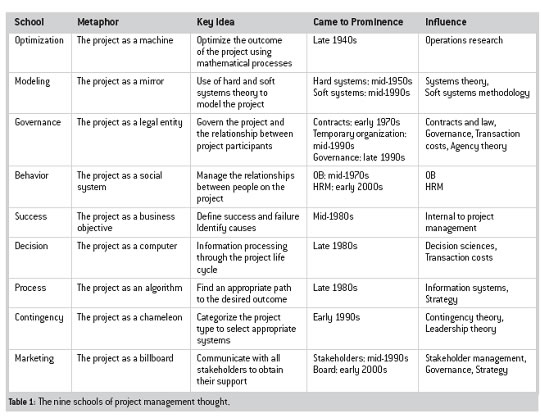

The goal of this document is to extend project management body of knowledge to a specific vertical industry. This is identified, as the second dimension of stretching is to broaden the PM scope. In this case automation system is not a non-traditional systems to PMI. (Bredillet, 2008)

How to conduct our research extension?

“Research can be conducted on how project management is affecting other disciplines such as engineering, construction, information technology, pharmaceuticals, marketing, and operations management.” (Bredillet, 2008)

“Despite the broadening use of systematic approaches to project management, the majority of related literature is focused on a handful of industries construction, engineering, government, information technology, and utilities that have, until recently, been the traditional areas for project management.”

Currently, the non-traditional project management areas include banking, pharmaceuticals, consulting, advertising, legal, health care, safety, and non-traditional manufacturing and industrial (automation systems) sectors (Kerzner, 2001).

Directions

In recognition of growth, scholars and practitioners have begun to include viewpoints generalized across the field as well as perspectives from specific industries.” (Carden, 2008)

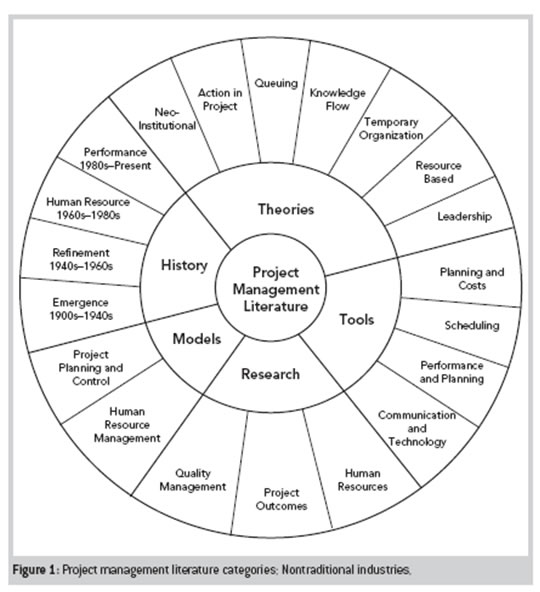

Research directions for non-traditional areas: (Carden, 2008)

(1) What is the availability of quality project management literature in non-traditional industries?

(2) What are the themes from the project management literature in non-traditional industries?

(3) What topics or themes from the project management literature may be generalizable to non-traditional industries? and

(4) What do systematically identified articles tell us about project management in the non-traditional areas identified?

Main Investigation

Step 1 – What is the availability of quality project management literature in non-traditional industries

The author has conduct researches on different academic and industrial journals, and literatures. A precise scope and definition of automation systems needed to be identified first since it the term “automation systems” is board, vague, and is interpreted very differently by different people.

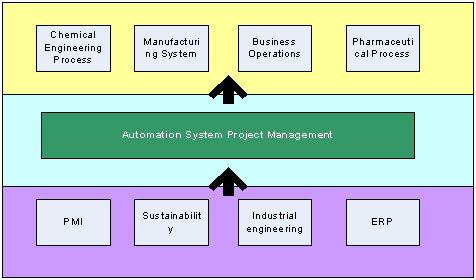

Just one quick search of the term “automation system management” can pull out literatures from a diverse set of professional area(s), such as chemical process, industrial and chemical engineering, control system, process control, medical systems, manufacturing systems, energy and environmental management, robotics, enterprise resource management, operation management, pharmaceutical process, etc.

Literatures

| Source | Area of Knowledge |

| Automation system, Wikipedia, 2011 | Main limitations and advantages of automation systems |

| A new Approach to Corrosion Monitoring. (Kane, 2007) | Chemical and industrial engineering traditional, processes |

| Chemical process industries (CPI), (LePree, 2009) | Diagnostics: Simplifying Optimisation. |

| Staying Alive, (Le Pree, 2009b) | Batch Process need further automation: Siemens systems; need advance control system & process control. |

| How to Implement a Manufacturing System? (Microsoft, 2003) | Common Issues on Automation System |

| Success in energy Conversation (Miller, 2011) | Energy best practices, technologies in energy management. (Green) |

| Industrial Engineering (Wikipedia, 2001) | Knowledge area(s) industrial engineering consist of |

| Part 1 – MES Benchmarking Survey Results; Automation Portal; Automation.com – (Lydon, 2011) | Integration Automation systems with ERP (Enterprise Resource Management) Solution Systems. |

| Lydon, Bill. (2011). | Pharmaceutical Automation Roundtable (PAR) |

Problem Definitions and Statement

From the literatures, automation systems can be anywhere in agricultural commercial or industrial sectors. However, the main theme “how to automate correctly or better”, itself becomes a vertical discipline alone. And this individual discipline itself may need skills, technologies, and knowledge’s from many other area(s).

Conceptual Mapping Framework of the Automation Systems Project Management

Example Mapping of the Automation Systems Project Management

Since the idea of automation system project management is relatively new and vague, we need to first carefully clarify our problem statement that is similar to a demarcation. For example, imagine yourself as a project management, how are you going to manage your automation projects in order to achieve results? What do you want to achieve at the end of the day? How can we use “projects” to handle those challenges?

In general what are the common challenges, missions and visions, in automation systems across different industries, that operation management face and feel painful everyday? Are those challenges specifically happening in automation systems only? Can we use existing PMI knowledge to resolve those challenges? How can we extend the existing PMI knowledge to cover managing those challenges?

Another point is, according to PMI, a project is a temporary endeavour, having a defined beginning and end (PMBOK, 2009), while automation systems is business as usual (BAU or operations), which are repetitive, permanent or semi-permanent functional work to produce products or services. We have to identify project management natured tasks or programs that can add value or positive long-term change of the automation systems operations. Such activities can be related to hands-on system or engineering implementation and changes, processes/architecture/ practices changes, or management strategies changes.

We need to clarify what PM plays a role in each kind of activities. For example, a PM is not going implement a robotic arm somewhere in the manufacturing process line, but the PM need to know how to create and manage a project so that experts can perform the implementation. We are not going to document how to perform querying analysis, system optimisation etc, although this can be root cause of many automation systems common problems. We focus on methods or ideas that PM can contribute to the success of the automation system operations.

Step 2 – What are the themes from the project management literature in non-traditional industries?

What are the current disadvantage, limitations, challenges and add values initiatives we are facing in automation systems?

Technical Limitation. Current technology is unable to automate all the desired tasks. (Wikipedia, 2011)

Security Threats/ Vulnerability : An automated system may have limited level of intelligence; hence it is most likely susceptible to commit error. (Wikipedia, 2011)

Unpredictable development costs: The research and development cost of automating a process may exceed the cost saved by the automation itself. (Wikipedia, 2011)

High initial cost : The automation of a new product or plant requires a huge initial investment in comparison with the unit cost of the product, although the cost of automation is spread in many product batches. (Wikipedia, 2011)

The impact of corrosion on assets and processes is great . Advances in technology allow engineers to assess corrosion in a whole new way, with real-time monitoring and the ability to link deterioration with process conditions. Author suggested implementing an appropriate and correspondingly dynamic means for corrosion appraisal , engineers can better manage industrial processes, corrosion prevention treatments , minimize corrosion upsets and failures , and minimize the availability . (Kane, 2007) – A new Approach to Corrosion Monitoring

Improved programming and interfaces: Chemical process industries (CPI) Improved programming and interfaces are making it easier for end users to marry process control , asset management and diagnostic data.

Poor / to be improved Diagnostic Infrastructure: The diagnostic phase uses a structured engineered approach, including in proven methodology and in-depth knowledge of systems and processes. It provides comprehensive testing and analysis of several processes performance indicators including high frequency analysis, process stability and control loops to measure performance and identify improvement potential. Existing process controls are being compared against industrial standards and benchmarks . The benchmark results information is helpful to identify and understand performance bottlenecks. (Le Pree, 2009) – Diagnostics: Simplifying Optimisation

Increasing flexibility, reliability and visibility: while decreasing batch cycle times via integrated automation systems can help increase throughput and the chance of survival. Automation can provide solutions that can help, such as using advanced process control on the existing batch process, further integration with enterprise resource planning systems allows, providing track-and-trace , documentation and historical analysis . (Le Pree, 2009) – Staying Alive

Energy best practices, technologies in energy management . (Green). Long-term, comprehensive energy conservation plans are the foundation. Investment in metering and communications infrastructure is crucial. The importance of interoperability data context in Energy Management Systems is key.

Management programs are developed and maintained by multi-disciplined teams of individuals from various functions such as maintenance, engineering, production, financing, and management.

Keywords: Data context, interpretability in Energy Management System (EMS) – collection and visualization of real-time energy data , interoperability with a variety of disparate systems. Success in energy Conversation (Miller, 2011)

Topics in Industrial Engineering

Operations research & Optimization techniques, Engineering economics, Supply chain management & Logistics, Systems Simulation & Stochastic Processes, System Dynamics & Policy Planning, System Analysis & Techniques, Manufacturing systems/Manufacturing engineering, Human factors engineering & Ergonomics, Production planning and control, Management Sciences, Computer aided manufacturing, Facilities design & Workspace design, Quality Engineering, Reliability Engineering & Life Testing, Statistical process control or Quality control, Time and motion study, Operations management, corporate planning, Productivity improvement, Materials management.

The various topics of concern to industrial engineers include management science, financial engineering, engineering management, supply chain management, process engineering, operations research, systems engineering, ergonomics, cost and value engineering, quality engineering, facilities planning, and the engineering design process. (Wikipedia, 2011 – Industrial Engineering)

How to Implement a Manufacturing System? Common Issues on Automation System (Microsoft, 2003)

Assessing Pain; Multiple drivers of change ( upgrade & maintenance on multi-platform, interoperability system; compatibility); Missing functionality (system do not accommodate actual costing); System down (Availability) issues. No Process visibility benefits.

Rolling Up Requirements : Individual needs to collective requirements, prioritizing needs. Departmental balance (visible executives, executive management, PMO?)

Change Management Issues (Transitional satisfaction, Rules of Engagement), Partner perspectives . Technology Vendor locked in . Original company who have handcrafted manufacturing system created a unique situation in that most staff were familiar looked for technology partner to offer process changes as the implementation progressed.

Training – increase awareness: (testing, commitment, feedback, micro-topics). Never enough; Trainer spend time training the stuff using real data.

Manage “Scope Creep”

> Assess whether there is a gap between the new needs and the current system’s out-of-box capabilities.

> Determine if an alternative to modification or third-party integration is possible, or if modification or third-party integration can be postponed.

Test the System; Run and Refine the System

Don’t Implement without Proper Settings

> Strong-willed project leader with time and resources;

> Representative project team with time and resources;

> Well-defined list of business objectives;

> Rigorously critiqued list of system requirements;

> Realistic but aggressive timeline;

> Thoroughly documented system procedures;

> Partner that is the right strategic fit with industry, manufacturing, and system experience; and

> Thorough testing that can uncover any problems and ensure a smooth kick-off.

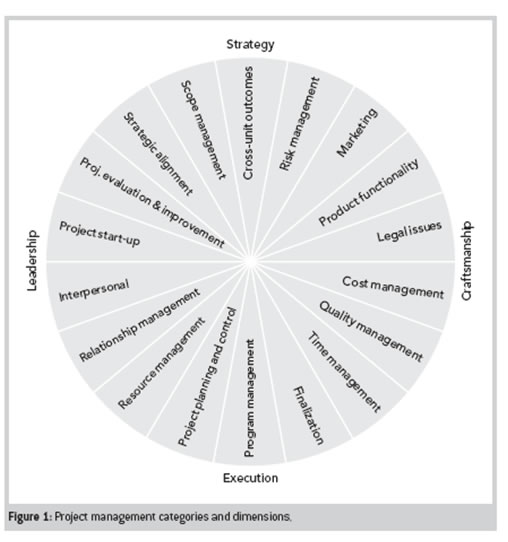

Step 4 – What topics or themes from the project management literature may be generalized to non-traditional industries?

List of existing themes or soon to be existing themes.

(Bredillet 2008)

Ingason (2009)

(Crawford, 2008)

Sources of Literatures

Below are the sources of Academic / Industrial Journals and Literatures. This would show the broadness automation systems project management span across.

Academy of Management Journal; Administrative Science Quarterly; Benchmarking; Human Resource Development; International Industrial Management & Data Systems; International Journal of Project Management; Journal of Enterprise Information Management; Journal of European Industrial Training; Journal of Management Studies; Journal of Workplace Learning; Journal of Systems Management; The Learning Organization; Management Decision; Management Science; Project Management Journal; Public Personnel Review; Scandinavian Journal of Management; Sloan Management Review

(Carden, 2006)

Reference

Bredillet (2008). Exploring Research in Project Management: Nine Schools of Project Management Research; PMI Journal Sep 2008

Carden, Egan. (2008). Does Our Literature Support Sectors Newer to Project Management? The Search for Quality Publications Relevant to Non-traditional\ Industries; PMI Journal (Sep 2008); Vol. 39, No. 3, 6-27

Lila Carden, Toby Egan. (2008). Does Our Literature Support Sectors Newer to Project Management? The Search for Quality Publications Relevant to Non-traditional Industries Project Management Journal. Sylva: Sep 2008. Vol.39, Iss. 3; pg. 6, 22 pgs

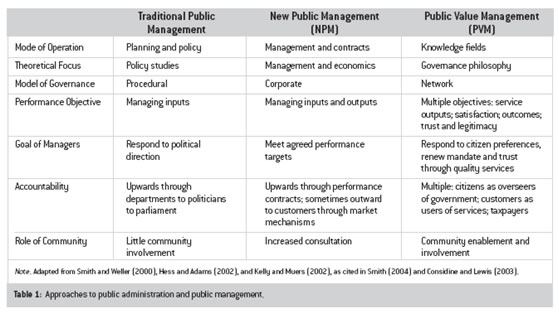

Crawford, Helm. (2008). Government and Governance: The Value of Project Management in the Public Sector; PMI Journal Sep 2008

Ingason, Helgi Thor, Jónasson, Haukur Ingi. (2008). Contemporary knowledge and skill requirements in project management Project Management Journal, Jun2009, Vol. 40 Issue 2, p59-69, 11p, 2 charts, 7 diagrams; DOI: 10.1002/pmj.20122; (AN41331844); PMI Journal Sep 2008

LePree. (2009). Simplifying Optimization, Chemical Engineering Nov 2009; 116, 12; pg 25.

LePree. (2009). Staying Alive, Chemical Engineering, New York: May 2009; Vol. 116, Iss. 5; pg. 25, 5 pgs

Lydon, Bill. (2011). Pharmaceutical Automation Roundtable (PAR) – Part 1 – MES Benchmarking Survey Results; Automation Portal; Automation.com

Kane. (2007). A New Approach to Corrosion Monitoring; Chemical Engineering; Jun 2007; 114, 6; pg.34

Miller. (2011). Cover Story: Success in energy conservation; Emerging best practices, technologies in energy management; ISA.org Technical News

Wikipedia. (2011). Industrial Engineering

Wikipedia. (2011). Automation Systems

The Author

Eric Tse is an international recognized expert/consultant in Enterprise Access and Identity Management Architecture Design and Implementation. He has been working with international renowned experts in information technology in many prestigious companies. He also pursues research interests in project management, financial models, application/enterprise/solution architectures, compilation technology and philosophy of science.

Copyright Project Perfect